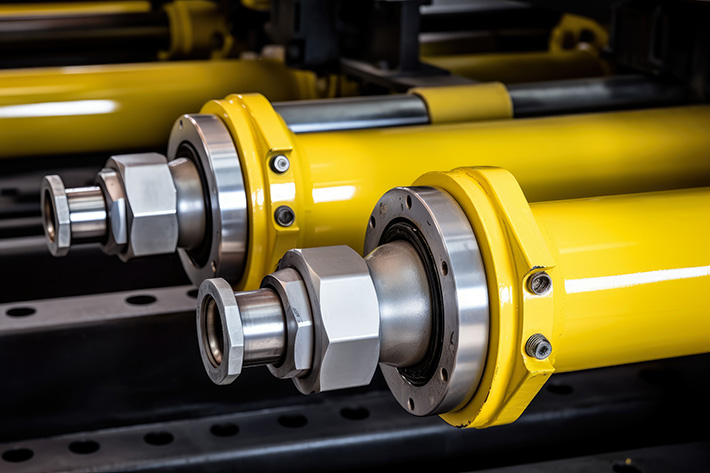

In today’s industrial and manufacturing environments, hydraulic cylinders play a critical role in the operation of various machinery and equipment. These devices convert hydraulic energy into mechanical motion, enabling powerful and precise movements. However, like any mechanical component, hydraulic cylinders are subject to wear and tear. When they malfunction or degrade, it’s essential to address the issue promptly to maintain operational efficiency. This comprehensive guide explores the key aspects of hydraulic cylinder repair services, offering insights into how these services can optimize equipment performance and prolong the lifespan of hydraulic systems.

Understanding Hydraulic Cylinder Repair Services

Hydraulic cylinder repair services are specialized maintenance and restoration processes aimed at diagnosing, repairing, and refurbishing hydraulic cylinders. These services are crucial for industries relying on hydraulic systems, such as construction, manufacturing, and automotive sectors. The primary goal of hydraulic cylinder repair is to restore cylinders to their optimal functioning condition, ensuring that they continue to operate efficiently and reliably.

Diagnosing Hydraulic Cylinder Issues

Before any repair work can commence, it is vital to accurately diagnose the problems affecting the hydraulic cylinder. Common issues include leaks, reduced performance, and physical damage. Technicians often perform a thorough inspection to identify the root cause of the problem. This may involve checking for signs of wear on seals and rods, assessing fluid levels and contamination, and evaluating the overall condition of the cylinder.

- Leak Detection: Leaks can be caused by worn seals, damaged hoses, or loose fittings. Detecting and repairing leaks is essential to prevent fluid loss and maintain system pressure.

- Performance Analysis: A drop in performance can indicate internal damage or contamination. Technicians assess cylinder stroke, speed, and load-bearing capacity to pinpoint issues.

- Physical Inspection: Visual and tactile inspections help identify signs of physical damage, such as scratches or dents on the cylinder body and rod, which can affect functionality.

Repair and Refurbishment Techniques

Once the diagnosis is complete, hydraulic cylinder repair services involve several key techniques to restore the cylinder’s functionality:

- Seal Replacement: Seals are critical components that prevent fluid leakage and contamination. Replacing worn or damaged seals is a common repair task that helps restore cylinder performance.

- Rod Reconditioning: The rod is subject to significant wear and tear. Reconditioning or replacing the rod ensures smooth operation and prevents further damage to the cylinder.

- Cylinder Honing: Honing involves smoothing the inner surface of the cylinder to remove wear and damage. This process helps restore proper sealing and reduces friction.

- Piston and Gland Replacement: Pistons and glands are essential for cylinder operation. Replacing these components as needed ensures that the cylinder maintains its operational efficiency.

- Fluid Replacement: Contaminated or degraded hydraulic fluid can affect performance. Replacing the fluid and ensuring proper filtration helps maintain system health.

Benefits of Professional Hydraulic Cylinder Repair Services

Engaging professional hydraulic cylinder repair services offers several benefits, including:

- Increased Efficiency: Properly repaired cylinders operate more efficiently, reducing energy consumption and improving overall system performance.

- Extended Equipment Life: Timely repairs and refurbishments help extend the lifespan of hydraulic cylinders, delaying the need for costly replacements.

- Reduced Downtime: Efficient repair services minimize equipment downtime, allowing operations to continue with minimal interruption.

- Cost Savings: Repairing rather than replacing hydraulic cylinders can be more cost-effective, particularly for high-value or custom cylinders.

- Expertise and Precision: Professional technicians possess the expertise and tools required for accurate diagnostics and high-quality repairs, ensuring reliable results.

Choosing the Right Hydraulic Cylinder Repair Service

Selecting a reputable hydraulic cylinder repair service provider is crucial for achieving optimal results. Consider the following factors when making your choice:

- Experience and Expertise: Choose a provider with extensive experience in hydraulic cylinder repair and a proven track record of successful repairs.

- Quality of Service: Evaluate the quality of service offered, including diagnostic accuracy, repair techniques, and customer support.

- Turnaround Time: Efficient repair services should offer reasonable turnaround times to minimize equipment downtime.

- Warranty and Support: Opt for providers that offer warranties on their repairs and ongoing support to address any issues that may arise.

- Cost Transparency: Ensure that the provider offers clear and transparent pricing, with no hidden costs.

Conclusion

Hydraulic cylinder repair services are vital for maintaining the efficiency and reliability of hydraulic systems in various industrial applications. By understanding the common issues, repair techniques, and benefits of professional services, businesses can make informed decisions to optimize their equipment performance. Engaging with experienced and reputable repair service providers ensures that hydraulic cylinders remain in peak condition, contributing to the overall success and longevity of industrial operations.